Discover how Mauro Electric installed a 1200A 3 Phase 480V service for Lenz Composting Station in Stanwood, WA, ensuring efficient and reliable operations.

At Mauro Electric, we pride ourselves on delivering high-quality electrical solutions for a wide range of industrial projects. Recently, we had the opportunity to work on an exciting project for the new Lenz Composting Station in Stanwood, WA. This case study details our process for installing a 1200A 3 Phase 480V service, highlighting the challenges we faced and the solutions we provided to ensure a successful installation.

Project Overview

The Lenz Composting Station required a robust and reliable electrical system to support its operations. The facility needed a 1200A 3 Phase 480V service to power its equipment, ensuring efficient and uninterrupted operation. Mauro Electric was tasked with designing and installing this critical infrastructure.

Initial Assessment and Planning

The first step in the project was a comprehensive assessment of the site and the specific electrical requirements of the composting station.

- Site Evaluation: We conducted a thorough evaluation of the site to determine the optimal location for the electrical service entrance and equipment placement.

- Load Calculation: Our team performed detailed load calculations to ensure the new electrical system could handle the station’s demands without risk of overload or failure.

- Coordination with Stakeholders: We collaborated closely with Lenz Composting Station’s management and other contractors to align our plans with the overall project timeline and requirements.

Designing the Electrical System

With the initial assessment complete, we moved on to the design phase, focusing on creating a system that was both efficient and scalable.

- System Design: Our engineers designed a 1200A 3 Phase 480V service tailored to the specific needs of the composting station. This included selecting appropriate transformers, switchgear, and distribution panels.

- Compliance and Permits: We ensured that our design met all relevant electrical codes and standards. Necessary permits were obtained from local authorities to proceed with the installation.

Installation Process

The installation phase was executed with precision and attention to detail, ensuring that all components were installed correctly and safely.

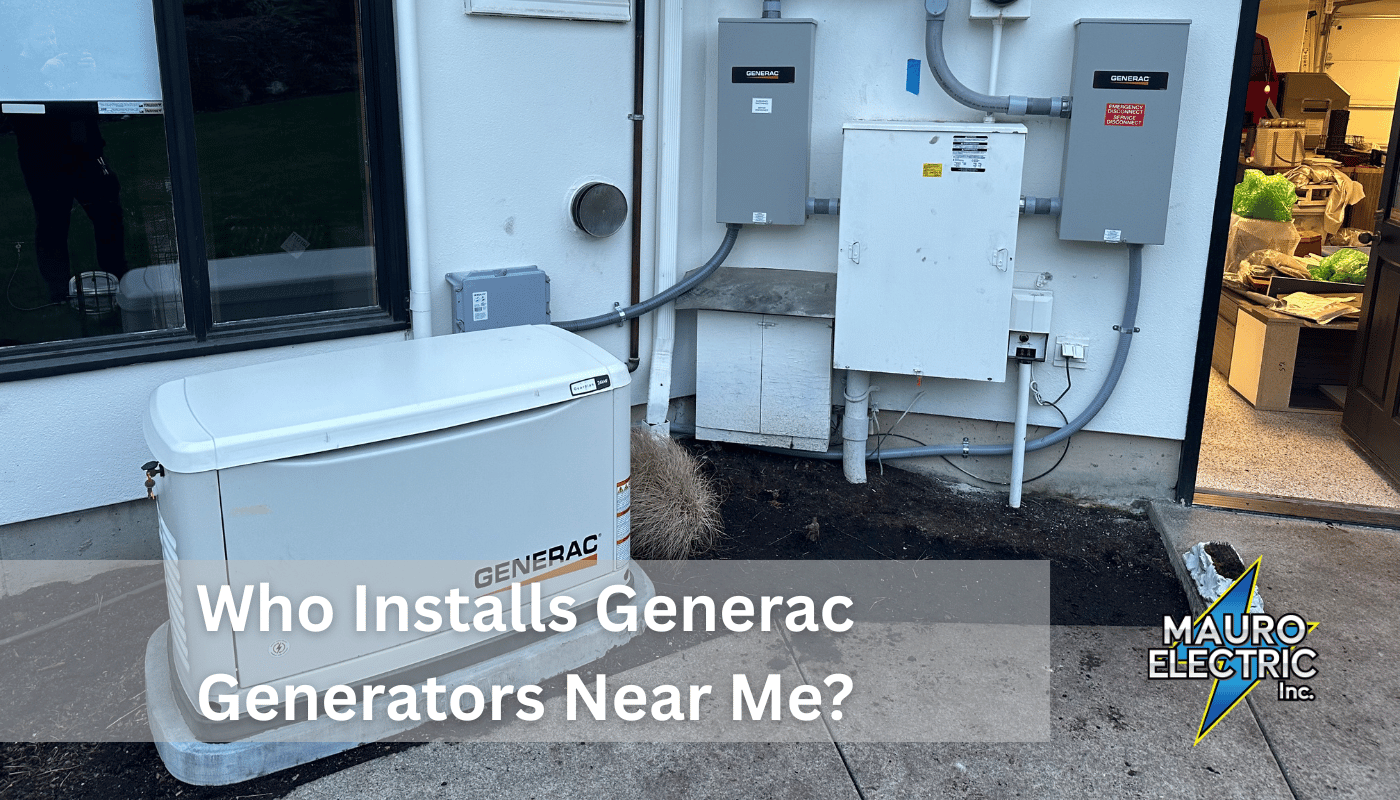

- Equipment Installation: We installed the transformers, switchgear, and distribution panels, making sure that all components were securely mounted and properly connected.

- Wiring and Connections: High-quality wiring was used to connect the various components of the system. Our team meticulously ensured that all connections were secure and compliant with safety standards.

- Testing and Commissioning: After installation, we performed rigorous testing to verify the system’s functionality. This included load testing and safety checks to ensure reliable operation.

Challenges and Solutions

Every project comes with its unique challenges, and this was no exception. Here are a few we encountered and how we addressed them:

- Site Conditions: The site had limited space for equipment installation. We designed a compact layout that maximized available space without compromising functionality.

- Coordination with Other Trades: Synchronizing our installation with other ongoing construction activities required careful planning and communication. Regular meetings and updates ensured smooth coordination.

Project Outcome

The successful installation of the 1200A 3 Phase 480V service at Lenz Composting Station resulted in a reliable and efficient electrical system that supports the facility’s operations.

- Enhanced Efficiency: The new electrical system provides the necessary power to operate heavy machinery and equipment, improving the overall efficiency of the composting process.

- Future-Proof Design: The system is designed to accommodate future expansion, ensuring that the composting station can grow its operations without major electrical upgrades.

- Customer Satisfaction: Lenz Composting Station management expressed their satisfaction with the quality of work and the professionalism of our team.

At Mauro Electric, we are committed to delivering top-tier electrical solutions that meet the specific needs of our clients. The successful installation of a 1200A 3 Phase 480V service for Lenz Composting Station in Stanwood, WA, showcases our expertise and dedication to excellence. If you have a complex electrical project, contact us today to learn how we can help you achieve your goals.

or call: (360) 654-770